Do you want to receive more information about homes?

We will be happy to provide you with all the information you need, answer your questions and accompany you throughout the entire process.

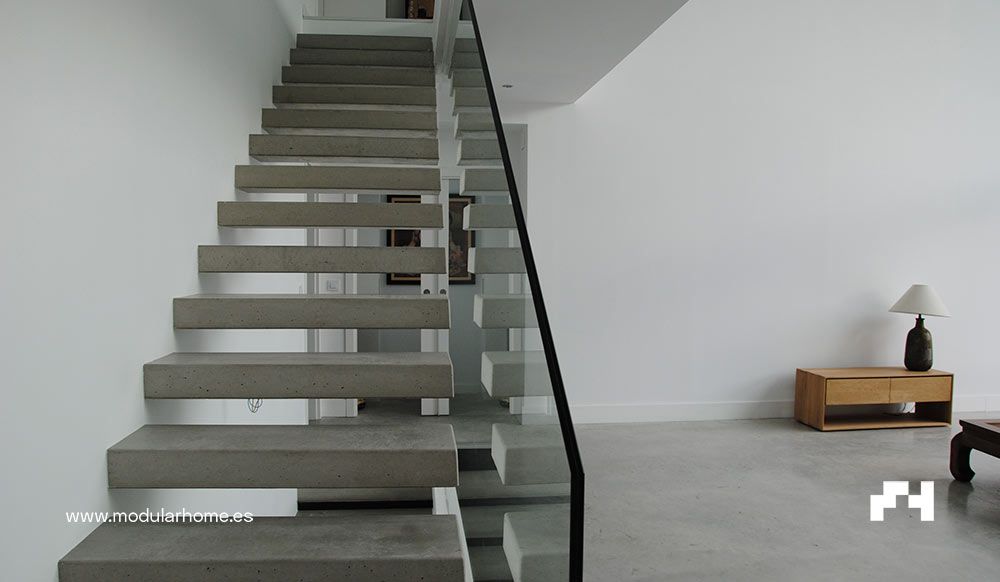

MH SYSTEM

High structural capacity and low maintenance

In our concrete construction system we must highlight the use of Concrete load-bearing panels with a double function: structural and enclosure.

The unification of the two functions reduces the total term of the work, since it is carried out the execution of the structure at the same time as that of the façade enclosure where each panel is a canvas, with a perfect finish and low subsequent maintenance.

We will be happy to provide you with all the information you need, answer your questions and accompany you throughout the entire process.

MH System, technology in your home

The construction system MH System It is based on a work system that goes beyond prefabrication itself. The objective is to get ahead of the work to think in advance about the construction solution and calculate the cost. This way the client can have a fixed price before the start of execution.

Our prefabrication system is open, that is, a construction method of modular houses flexible that is not based on modules of fixed measurements, but adaptable to any project, within what we call Standardized Personalization.

In the MH construction system, the industrialized elements are divided into two phases:

Modular housing structure using architectural reinforced concrete panels and prefabricated slabs.

Interior distribution through industrialized partitions and housing installations.

The rest of the materials that make up the house are a choice based on functionality and aesthetic criteria customized by the client, within standards of finishes very competitive prices.

concrete filling

Delivery mesh

Caviti type foundation

Perimeter band

Anti-moisture PVC sheet

Cleaning concrete

gravel lining

Natural level terrain

alveolar slab

Metal coping

MH supporting panel

Mineral wool insulation with vapor barrier

Galvanized steel assembly with fiberglass insulation (e=70mm)

laminated plasterboard

Flooring

leveling plate

Radiating floor

XPS insulation

Anti-radon sheet

We are manufacturers and we guarantee the final result of the product. We have the technical structure and production necessary to undertake the work with professionalism and precision.

Our construction philosophy

For Modular Home, a house is a controlled industrial process. The process begins with the design and breakdown that is developed through a study. It is then manufactured according to the technical specifications of the project and has its last phase at the installation site of the prefabricated house.

Thus, Errors are minimized and complete traceability of the process is obtained of execution. To do this, our team of professionals controls and analyzes the roadmap, as well as the execution of each batch of work before continuing with the next, guaranteeing the quality of our product and consolidating the advantages of our brand.

The team of architects works closely with clients to design their home, taking care of every detail and ensuring that their expectations and needs are met.

Manufacturing experience, supported by our most advanced technology, allows us to control the quality of each phase of the work in progress.

Our assembly team precisely installs homes on location, meeting standards and ensuring quick delivery of your modular home.

Explore our selection of prefabricated homes: style and comfort at your fingertips.

Prefabricated designer house in Villamayor, Salamanca

Plot + Detached Villa in Urb. Los Silillos, Valdetorres de Jarama, Madrid 2

Modular Plus in Urb. Los Silillos, Valdetorres de Jarama 1A

Modular Housing in Becerril de la Sierra

Townhouse in Leganés

Plot + Modular House in Valdetorres de Jarama, Madrid 1B

Author's House in Torrelodones, Madrid

Custom House with Uneven Level in Madrid

Author's House in Alicante

Prefabricated house in Marbella, Málaga

Prefabricated house in Las Rozas de Madrid

Prefabricated housing in Majadahonda, Madrid

Prefabricated housing in El Espinar, Segovia

Prefabricated housing on the outskirts of Madrid

Rustic modular home in Fiscal – Huesca

Prefabricated Housing in Guadalix de la Sierra, Madrid

Return Modular Housing in Pozuelo de Alarcón, Madrid

Design Single Family Home in Las Rozas de Madrid

Single-family home in Madrid

Prefabricated housing in Barcelona

Model MH Design

MH Rustic Model

Kahlo model

Rothko model

Picasso model

Gabarrón Model

Model Vilalta

Dali model

Cava Model

I-Home Model

Qualities that adapt to you

The qualities that make up the home are a choice based on the level of finishes, functionality and aesthetics chosen by the client. From the MH System construction system, two types of finishes defined in the different Quality Memories plus the choice optional of the Custom Packs.

Contact us for more information

Ready to start your project?

We are committed to providing you with the best experience in building prefabricated homes in Spain and Portugal. If you have any questions, comments or want a personalized quote, fill out this form and we offer you a complete advisory service.

Here you will find answers to the most common questions that our clients usually have. If you have any additional questions, please do not hesitate to contact us.

Both structural systems comply with the CTE and can be used in the construction of homes in Spain. We are going to talk to you about our system using concrete load-bearing walls, because we consider that it has many advantages over other systems, and now it is what architects are using the most.

The reinforced concrete structural system (it also has iron inside) is made up of x load-bearing concrete panels and they function as load-bearing walls, that is, the weight of the house rests on each linear meter of wall and not on pillars (like the case of metal structures) that in the event of a seismic movement can “come off” and possible collapse of the building.

It allows great flexibility in the design of the house, avoiding annoying pillars in the entire architecture.

Concrete is also an excellent acoustic insulator and since the entire façade and even floors are made of concrete, you can enjoy a lot of privacy. The metal structure does not include the façade of the house, and therefore, we can say that they do not have this characteristic and it will depend on the skins that are placed on top. The greater the number of skins or layers, the cost of the work increases.

In addition, concrete has a great thermal inertia, which makes it easier to distribute the air conditioning in a natural and homogeneous way on the floor and walls.

Finally, polished load-bearing concrete panels on the façade, as is the case with Modular Home, have zero maintenance costs over the years. In the case of metal structures, the enclosure is made of brick and is usually covered with a porous mortar that deteriorates over the years.

ModularHome:

Where we are:

SUBSCRIBE TO OUR NEWSLETTER

Log in

Access to obtain updated information about the status of your modular home and explore the multiple advantages that Club MH offers you.